For overseas importers, wholesalers, distributors, and funeral supply companies sourcing slant headstones, a clear understanding of manufacturing, materials, customization, quality control, and international shipping is essential for reliable OEM partnerships. Producers specializing in slant-style memorials combine traditional stone-working techniques with modern CNC and laser technologies to deliver consistent products that meet cemetery regulations and market expectations. Buyers should evaluate a supplier’s production capabilities, material sourcing, and sample approval processes before committing to large orders.

Granite remains the preferred material for these monuments due to its durability and wide range of colors and grain patterns. Typical choices include dark absolute black, blue-black, and gray granites as well as lighter tones when required. The manufacturing workflow starts with block selection and sawing, followed by CNC profiling, edge shaping, and polishing. Surface finishes commonly offered include high-gloss polishing, honed or matte finishes, and sometimes textured treatments. Manufacturers also work with other stones like marble for lighter-weight memorials, but granite is favored for long-term outdoor resilience.

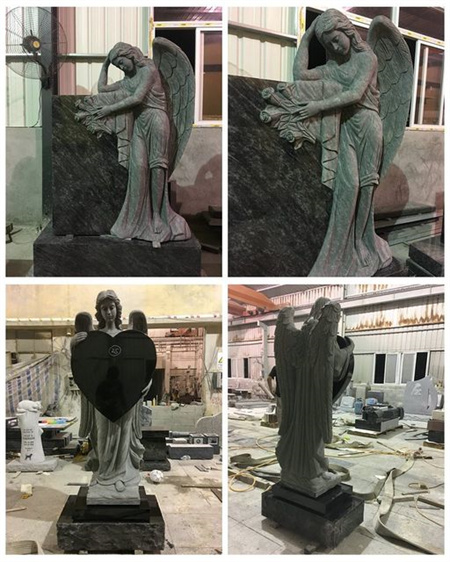

Customization is a core component of OEM supply for memorial products. Slant headstones can be tailored in dimensions, face angle, base design, and edge profiles to suit cemetery plot requirements or client preferences. Lettering and imagery use sandblasting or laser etching depending on the depth and precision required; color inlays, gilding, and bronze or stainless plaques are available for added detail. Many factories provide design proofs and photo-realistic mockups for approval, and can accommodate custom templates, logos, and epitaphs to align with a distributor’s product line.

Quality control in tombstone manufacturing addresses both material integrity and finished appearance. Reputable producers perform incoming raw material inspections, checking for fissures, density, and color consistency. Production-stage controls include dimensional checks with digital calipers, monitoring of CNC settings, and polishing inspections to ensure uniform surface quality. Final QC typically involves verifying engraving depth, alignment, and adhesion of inlays or metal components, as well as applying sealants where appropriate. Documentation such as inspection reports and photographic evidence can be supplied to buyers as part of the OEM process.

International logistics for heavy stone products requires careful packaging, proper documentation, and experienced freight coordination. Slant headstones are normally secured on wooden crating or heavy-duty pallets, separated with foam or timber supports, and fixed using straps to prevent movement during container shipping. Exporters should comply with ISPM 15 for wooden packaging, and provide necessary paperwork including commercial invoice, packing list, bill of lading, and certificate of origin. Common shipping options include FCL and LCL containers under FOB or CIF terms; buyers often arrange insurance and select carriers experienced with fragile, heavy cargo.

Production capacity, lead times, and minimum order quantities vary by supplier but are critical considerations for wholesalers and distributors. Lead times typically range from several weeks for stock styles to multiple months for fully customized runs. Sample production and approval rounds help align expectations on finish, engraving style, and dimensions. Clear communication regarding cemetery regulations, local standards, and preferred materials prevents costly rework and ensures smoother customs clearance.

In conclusion, successful procurement of slant-style headstones from OEM manufacturers depends on assessing material selection, customization capabilities, robust quality control, and competent international shipping practices. Importers and distributors benefit from inspecting factory processes, securing detailed specifications, and agreeing on documentation and logistics terms to ensure timely delivery of compliant memorial products.